6 RULES TO TAKE YOUR HARDWARE PRODUCT FROM CONCEPT TO MARKET

Xekera Systems has collaborated with hard-working entrepreneurs and experienced businesses for over ten years, yet the most common question asked is the most basic: “I have a product idea; what do I need to make it a reality?” Although the answer boils down to CAD and Eagle files, there is more to a product than physically making it. Those who have succeeded in manufacturing a product have followed these ten rules to develop a product and get it into the market.

1. Write a Good Product Requirements Document (PRD)

This is the first step in developing a product. There are many steps to writing a good PRD. Check out our page on PRDs and view our template to get started. This document can help creators identify aspects such as purpose, functional requirements, usability requirements, constraints, assumptions, performance metrics, and any technical or product-specific details necessary to the product. These are questions that go beyond a general picture of the product. Identifying them helps creators understand the resources required to bring products to life. Additionally, this process will help prioritize features according to their importance.

2. Build a Business Model Canvas

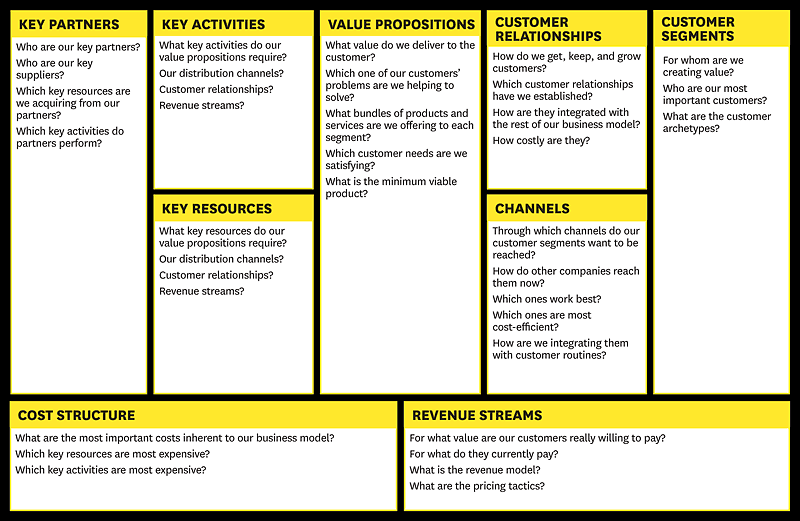

A business plan is an essential part of organizing and leading a company. However, many inexperienced business owners spend too much time writing down a plan and not as much time executing it. And then, if changes are made over time without updating the business plan constantly, it quickly becomes outdated. Since new companies continually evolve, they shouldn’t waste their time with long documents but instead, work on an overview of each business plan section that focuses on goals and facts. That is a business model canvas. This document can help answer critical questions regarding the feasibility of a specific project or entire business. Important topics are covered, like the target audience, how to monetize the product and turn a profit, intellectual property (patents, trade secrets, brand, copyrights), and more.

Example of the questions asked in the business model canvas

A Tip on Intellectual Property: Hire a lawyer and protect valuable IP if possible and necessary. Companies must first research whether an idea can be patentable (it’s no fun to pay a lawyer thousands to find out a product cannot be patented or already has been). Creators tight on funds are better off saving the cash and working on the business model canvas while doing market research to see if people want to buy it before spending too much time on the patent. There are also accessible online resources for brave creators who wish to file for the patent themselves.

3. Find a Good Product Design Firm

Many design and prototyping companies will take a product document and turn it into a physical product. Google "hardware development" and find several companies that can help. Companies like Xekera Systems look for specific things from their clients that let the firm know there is a healthy future ahead. For firms like Xekera Systems, business comes from building products for clients, not copying their ideas and brands — our resources are allocated for research and development in manufacturing. We focus more on production and less on supply chain development, advertising, and everything else that is required to bring a product to the market. Additionally, when shopping for a development firm, ensure they understand the manufacturing process well. Experienced firms can change a design to optimize it for manufacturing, a process known as DFM.

4. Budget for a High-Quality Prototype

Xekera Systems takes prototyping seriously, and we encourage you to do so too. Very few high-quality, ethical firms take equity in an idea in return for free prototyping and manufacturing. Companies like Xekera get hundreds of pitches for the latest and greatest gadget. Manufacturing firms have high overhead costs associated with engineering talent and equipment. These firms can’t afford to work for free in hopes of getting paid later. This makes development costs one of the most significant initial barriers for companies. We encourage creators to spend more and spend wisely early in the process to ensure their prototype is designed for manufacturability. Hardware is hard — by that, I mean timely and costly — due to all the revisions that need to be made as the product has already started. So for an average hardware product, expect to pay $50,000 to $100,000 for the R&D and prototyping. Regional pricing and the specifics of the project also play a significant role. Lastly, remember that this development process can take 3 to 6 months.

Early prototypes often look unimpressive, but allow creators to learn

5. Build a Brand and a Website

After choosing a great engineering team like Xekera Systems working on a product, it’s time to get an excellent webpage together. Creators can use a website building platform like Squarespace or Webflow to create something or hire a designer for about $1,500-$3,000. Using ready-made templates with built-in e-commerce features can save companies thousands of dollars in labor and research. However, this is the customer-facing part of the entire process, and business owners must use this opportunity to impress. Spend time and money to develop cohesive branding, a beautiful logo, and a compelling website. In today’s day and age, if a website isn’t up to par, chances are that people will not bother looking at the product.

6. Get Pre-Orders

After creating a website, it is time to put it to work — start collecting emails and taking pre-orders. Customers will buy a product pre-stage at a discount or give out their emails for an extra carabiner, keychain, or t-shirt. This is a great way to gather early feedback from other people who may be interested and an efficient way to test a product idea before spending thousands of dollars on manufacturing.

These six rules have developed over time thanks to dozens of engineers working on hundreds of products over a decade. Of course, this article doesn’t cover every granular aspect of manufacturing, but it serves as a starting point. Let us know in the comments: What topics are vital in the manufacturing process? If you have questions, let’s discuss your project and request a free quote for various services.